Barcode window for flight cases

Together with Protonic Software, the leading provider for the Rental Software Easyjob, we can offer a specially-developed barcode window for cases and trunks.

Contents within the cases which are fitted with this feature can be easily identified using a barcode system without having to open the lid, which saves not only time but also money.

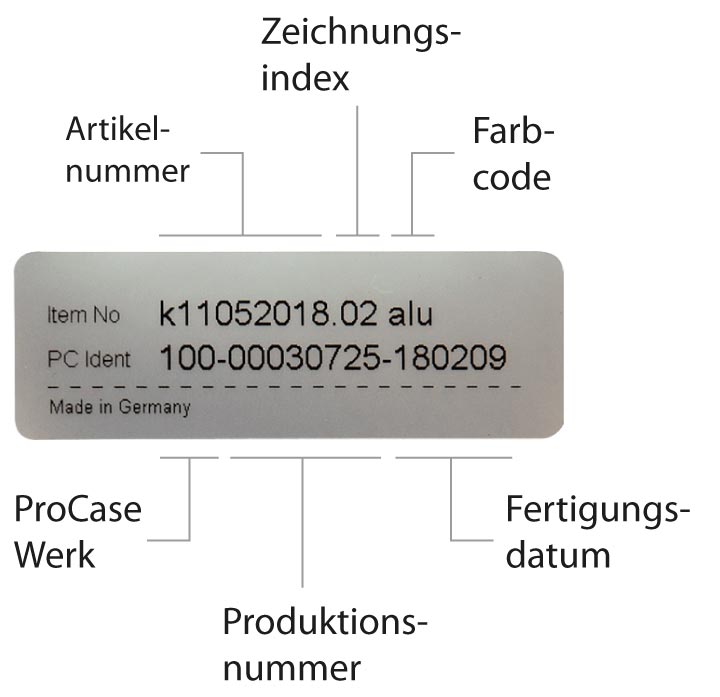

PC ID label

Every ProCase product has its own identification sticker (PC Ident Label). This gives information as to which item No. the case has, which level of change the item was built to and when it was made and in which ProCase plant.

This lets you identify ProCase products quickly and clearly. This is extremely useful when reordering any of ProCase’s products.

Handling information according to ISO 7000

DIN pictorials on transport packing in the form of handling instructions give forwarders and freight companies in particular clear instructions on the handling of packages and are therefore essential on any logistics container.

ProCase packing systems are available with the usual handling instructions printed on them. Handling information is to the standards as follows: ISO 7000 and EN ISO 780, which are internationally recognized.

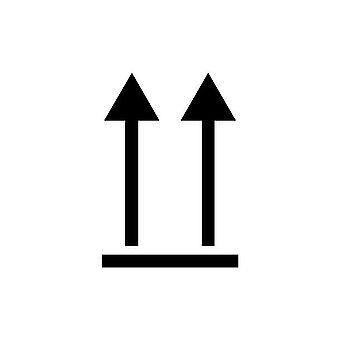

Top

Symbol ISO 7000 No. 0623. Indicates the upright position of the package. Template 80mm, Item No. 091981. Template 115mm, Item No. 091982.

Keep dry

Symbol ISO 7000 No. 0626. The package must be kept in a dry environment. Template 80mm, Item No. 091983. Template 115mm, Item No. 091984.

Fragile

Symbol ISO 7000 No. 0621. The contents of the package are fragile and must therefore be handled with care. Do not drop or sling. Stacking allowed. Template 80mm, Item No. 091985. Template 115mm, Item No. 091986.

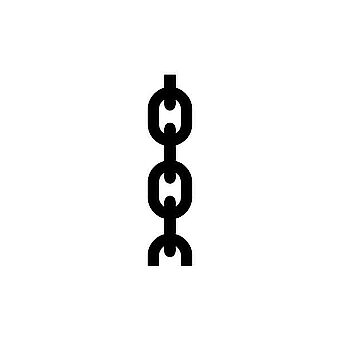

Slinging allowed

Symbol ISO 7000 No. 0625. Slinging equipment must be applied as shown in order to lift the package. Template 80mm, Item No. 091987. Template 115mm, Item No. 091988.

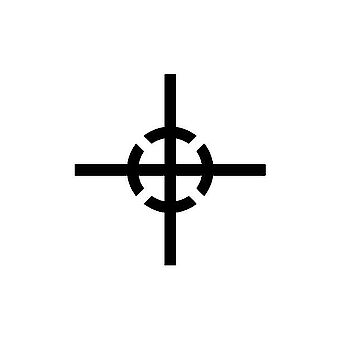

Centre of gravity

Symbol ISO 7000 No. 0627. Indicates the centre of gravity of a package that is to be handled as a single unit. It is recommended that this symbol is affixed on 2 sides plus the top side if the centre of gravity does not lie centrally. Template 80mm, Item No. 091989. Template 115mm, Item No. 091990.

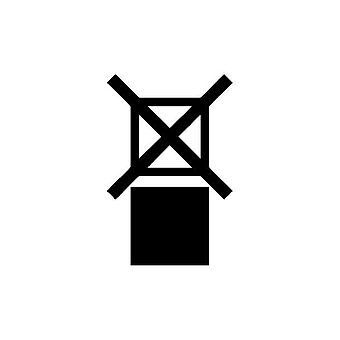

Do not stack

Symbol ISO 7000 No. 2402. Stacking of the packages is not permitted and no loads should be placed on the package. Template 80mm, Item No. 091997.

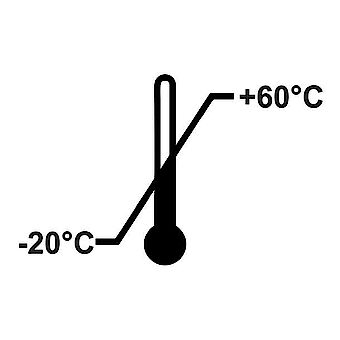

Permitted temperature range

Symbol ISO 7000 No. 0632. Indicates the temperature range within which the package must be stored and handled. Possible minimum and maximum values: -10°C - + 40°C (115mm: item No. 092104T1), -20°C - + 60°C (115mm: item No. 092104T2).

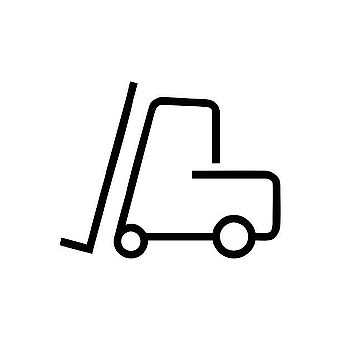

Do not use fork lift truck here

Symbol ISO 7000 No. 2406. Use of fork lift is only permitted at those points indicated. There is also the opposite symbol available.

Use fork lift truck at this point

Symbol ISO 7000. Sticker 115 mm: Item No. 0925011.

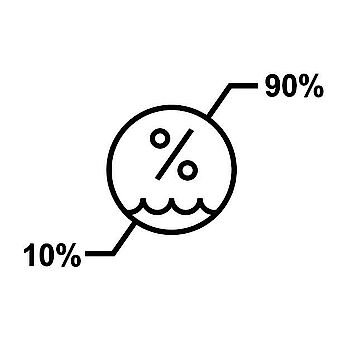

Permitted humidity area

Symbol ISO 7000 No. 2620. Value given = relative humidity (RH), 10%RH - 90%RH (115mm: Item No. 092107L2), 30%RH - 75%RH (115mm: Item No. 092107L1).

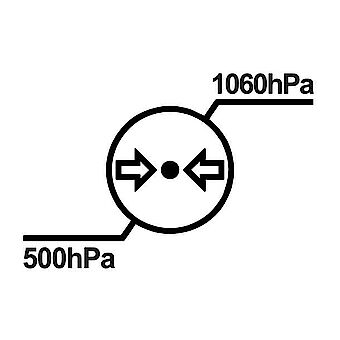

Permitted pressure area

Symbol ISO 7000 No. 2621. Value given: 500 hPa - 1060 hPa.

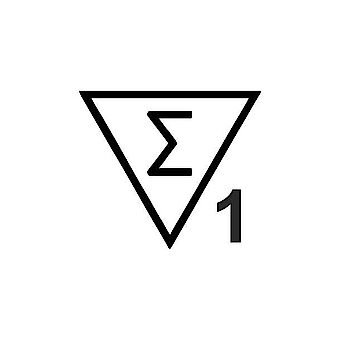

Container sufficient for 1 piece

Symbol DIN EN, No. 5.14. Gives information as to how many pieces of equipment or parts the container may hold.

Using indicators, you can check whether your goods and equipment have been correctly transported

When sensitive goods and equipment are transported, you can see if they have been carried in a correct and proper manner, using various indicators. These indicators register impacts, drops, rough handling, damage through tilting, humidity or non-observation of the temperature requirements.

Should your goods arrive defective, it can be seen which of the transportation requirements for the trunk were not held.

Do not send any goods without proper transport monitoring.

Transport monitoring indicators for trunks

- Shockwatch sticker: indicator for impacts (cannot be reset)

- Drop n’ tell: indicator for impacts from one direction (resettable)

- Tiltwatch: tilting indicator for upright transportation

- Digital min / max thermometer with memory

- Humidity indicator with check window

Shockwatch indicator

Item No. 08738

Drop N Tell

Item No. 08739

Humidity indicator

Item No. PCM-Feucht

Min Max thermometer

Item No. k19125002-04