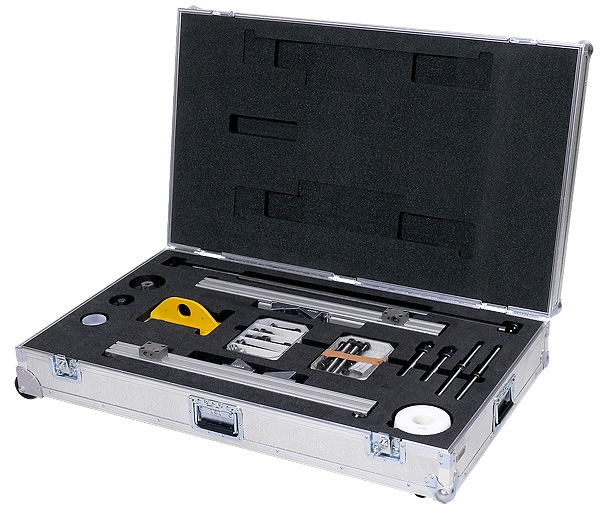

Precision cushioning and partitioning for transport boxes

An excellent and well-thought out interior is the strength of ProCase’s transport boxes. The correct interior with partitioning and precise cushioning guarantees a tidy content and the highest level of transport safety. Everything can be found easily and well-ordered in the transport box.

The ProCase interior design gives the transport box a functional and easy to use packing system.

Partitions and engineered retainers for components for the flight cases

So that all your parts and equipment are organized and held safely in the flight case itself, it is fitted with a partitioning system or foam inlays.

CNC-machined and engineered partitioning

The shapes of the sidewalls and retainers of ProCase products are machined using modern CNC technology. This makes them precise and reproducible. Partitioning is engineered into the flight cases which make them an integral part of the product. This method lets especially heavy parts be secured in a way whereby transport safety can be guaranteed. An additional cushioning of foam and felt protect the surfaces of your equipment.

Compartments and variable partitioning

If compartments are needed in order to divide the interior, we recommend, where possible, a variable solution. This gives you the option at a later date of varying the compartments by simply “unplugging” the partition walls and moving them to a more suitable position.

Variable partitioning systems can be found in many "standard" ProCase flight cases

- Vario-Flex universal transport flight case

- Floodlight cross-partitioning for Vario-Flex

- Screen FlexCases – variable LCD / Plasma cases

- TFT FlexCases – variable flight cases for computer screens

- Partitioning systems for PackCases

- Support case – universal trolley-type flight case

- In drawers of cabinet cases

Flight case with machined retainers

Flight case for a moving light featuring machined partitions and hard foam

CNC-machined retainers, fitted with felt

Robust interior partitioning for heavy parts

Variable Vario-Flex fitting out

Cross-partitioning system for floodlights

7mm partitioning in slotted foam

Fixed long partition plus variable partitioning in slotted foam

Accurately-fitting hard and soft foam inlays for cases

Tools and equipment are bedded into foam inlays like a nest, giving them an exact cushioning.

Hard foam inlay

Foam inlays are manufactured either hard or soft, according to need. Hard foam inlays are CNC-machined, CNC- water jet cut or stamped. Hard foam inlays can also be engraved by laser giving them that extra-special look. This adds to the value of their appearance.

Soft foam inlay

Soft foam inlays are either stamped or cut to shape. Shape-cutting is especially suitable for cylindrical objects.

Programming and tooling costs for foam inlays

A program must be written for all CNC-machined or water jet cut foam inlays, which is subject to a one-off charge. For single cases or small batches, a CNC-machined foam inlay is, in most cases, the most reasonable.

Stamped shapes or shape-cutting also incur a one-off tooling charge, whereby the costs become reasonable when ordering larger, total amounts.

Shaped cut-outs

CNC-machined part with laser engraving

Water jet part

3-layer stamped part

SIP integral foam in the flight case offers the best-possible transport protection

What is SIP?

SIP stands for “Superior Impact Protection” – an especially high protection system. The term was first coined in the automobile industry in the crash protection systems that were developed there and since then has been used also for polyurethane integral foam for flight cases.

Rubber-like toughness outside – softness inside

Polyurethane – commonly abbreviated to PU, is formed in a mould, whereby a rubber-like skin is formed on the outside, leaving a soft, airy inside. The SIP integral foam inlay is thus compact, being from one mould. SIP is easy to clean, hygienic and offers good damping protection and therefore excellent transport security when used in flight cases.

SIP integral foam